The

milling is a machining process in which, a rotary cutter is used to

remove the material from work piece in the direction perpendicular to

the axis of rotation. The

milling process is done by the machine, which hold both the tool and

work piece in jig and fixture, known as milling machine. There

are two ways to cut the material from the work piece through milling

machine. First one is named as conventional milling or Up milling and

the other one known as climb milling or down milling. The main and basic

difference between up milling and down milling is the direction of

rotation of cutter to the feed.

The milling operation is used to face those work piece, which are not symmetrical from its axis. It is also used to cut pockets, drill, slot and shape the work piece according to the requirement.

The milling operation is used to face those work piece, which are not symmetrical from its axis. It is also used to cut pockets, drill, slot and shape the work piece according to the requirement.

There

are two ways to cut the material from the work piece through milling

machine. First one is named as conventional milling or Up milling and

the other one known as climb milling or down milling. The main and basic

difference between up milling and down milling is the direction of

rotation of cutter to the feed.

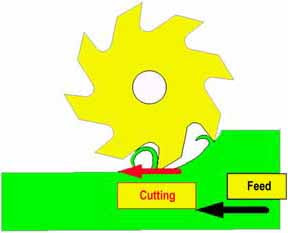

In

up milling the cutter rotates clockwise when cutting the work piece

from right to left. In this type of milling the tool spins against the

direction of feed. In this milling process, the cutting chips are

carried upward by the tool.

|

Up Milling

|

Down Milling

|

|

In up milling the cutter rotates against

direction of feed.

|

In Down milling, the cutter rotates with

direction of feed.

|

|

It is also known as conventional milling.

|

It is also known as climb milling.

|

|

In this, chip width size is zero at initial

cut and increase with feed. It is maximum at the end of feed.

|

In this cutting process, chip size is maximum

at start of cut and decrease with the feed. It is zero at the end of feed.

|

|

In this process, heat is diffuse to the work

piece which causes the change in metal properties.

|

In down milling most of heat diffuse to the

chip does not change the work piece properties.

|

|

In up milling, tool wear is more because the

tool runs against the feed.

|

In this, tool wear is less compare to the up

milling, due to the cutter rotate with the feed.

|

|

Tool life is low.

|

Tool life is high.

|

|

The cutting chips are carried upward by the

tool so known as up milling.

|

The chips are carried downward by the tool so

known as down milling.

|

|

The cutting chips fall down in front of the

cutting tool which again cut the chips cause less surface finish.

|

The cutting chips fall down behind the tool.

This gives better surface finish.

|

|

Due to upward force by tool, high strength

zig and fixture required to hold the work piece.

|

In down milling, downward force act on work

piece normal zig and fixture required.

|

|

|

|